Product center

合集 6

合集 6

-

EVA擠出發(fā)泡生產(chǎn)線

總共 4 個(gè)視頻

-

PE片材擠出機(jī)

總共 4 個(gè)視頻

-

XPS裝飾線條生產(chǎn)線

總共 2 個(gè)視頻

-

爆米花機(jī)

總共 2 個(gè)視頻

-

超臨界CO2注入系統(tǒng)

總共 2 個(gè)視頻

-

Hotline

0535-8610058

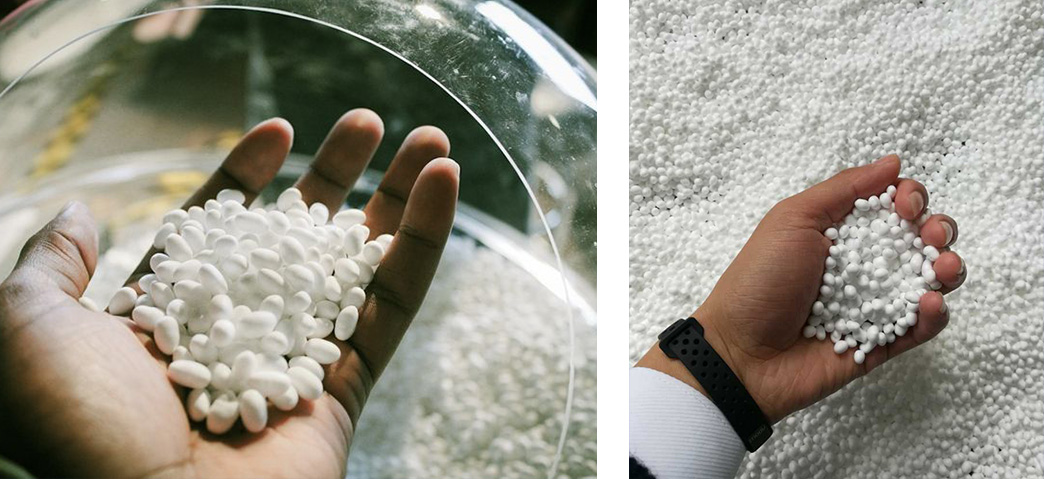

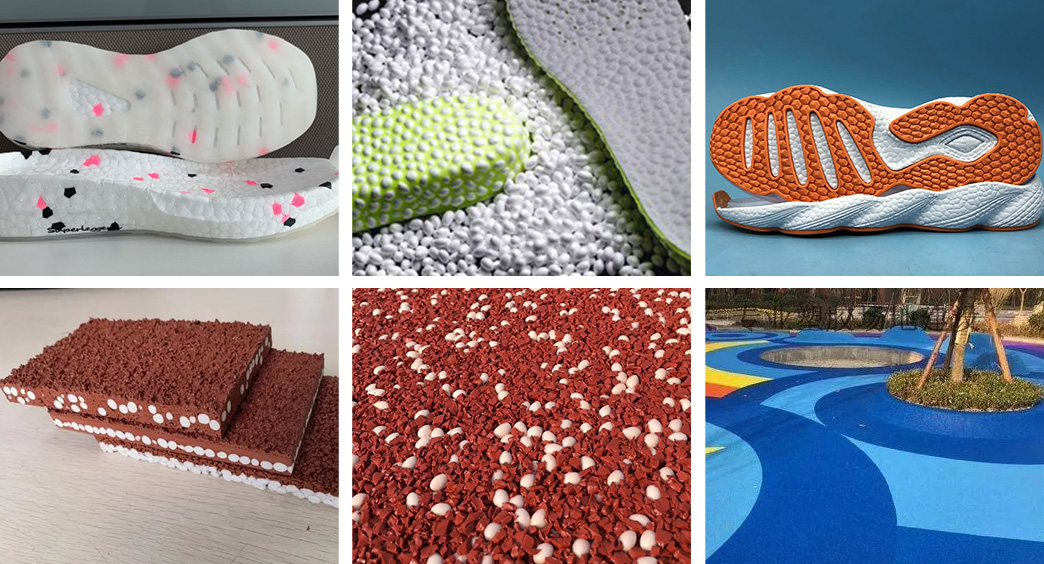

Introduction to supercritical CO2 foaming particle (popcorn) equipment: The equipment has introduced advanced German technology and is in the leading level in the same industry in China. It has the advantages of simple operation, stable performance, low waste rate and high automation. E-TPU foam particles and EVA particles produced by CO2 foam technology are widely used in the soles and insoles of various sports shoes. Compared with the foam particles produced by traditional technology, they are lighter, more elastic, and have excellent cushioning and shock absorption effects. The soles produced by this product are known as popcorn soles in the industry image. EPP foamed particles are widely used in takeout incubators, surfboards, helmet internal frameworks, car crash parts, interior materials of some outdoor seats, various high-quality toys, etc. due to their low cost, light weight, impact resistance, diverse density, good heat insulation, colorability, recyclability, etc. The CO2 foaming particle equipment can be used for many purposes, which can meet the different needs of different customers. If you are interested, please call.

| Model | YG-TPU120 | ||

| Foam Agent | CO2 | ||

| Granule | E-TPU grain | ||

| Ratio | 1-8Times | ||

| Capacity | 100-180 kg/hr | ||

| Actual Power | About 50 kw | ||

| Power | 175 kw | ||

| Voltage | 380V 50Hz | ||

Follow us

Follow us

Popular keywords:

Popular keywords: